Estd. 1987

Sales: +91-9810112341 | Technical Support: +91-9212268113

Delhi ι Gurgaon

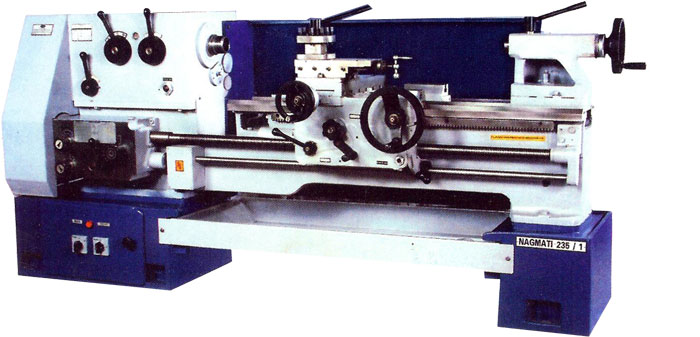

Special Features

Rigidity and heavy duty performance

• Robust IS 25 graded castings.

• Rigid and box section type extra wide bed provides maximum torsional stiffness.

• Rigid and accurate, alloy steel, hardened & ground man spindle mounted on precision taper roller bearings.

• Speeds range from 35 to 1500 RPM with 5 HP motor.

• Force lubrication in headstock.

• Apron with oil bath.

• Interlock for thread and feed mechanism (only one can be engaged at a time).

• Full length cross slide to accommodate rear tool post or copying attachment.

• Heavy square body tailstock with 60 mm sleeve.

• Sliding type coolant and chip tray.

• Electrical overload protection through relays and contactors.

Built-in accutacy :

• All major casting artificially seasoned for retaining built-in accuracy.

• Critical components precision machined on imported mother machines.

• Induction hardened and ground and alloy steel gears mounted on precision spline shafts & running in oil bath.

• Flame hardened and ground bed for minimum wear.

• Alloy steel lead screw threads cut on WMW thread milling machine.

• Each machine tested to IS: 1978 (Part l) 1993.

Versatility:

• Built-in gap bed.

• Extra height of centers for larger jobs (optional).

• Norton gear box for selection of wide range of feeds and threads.

• Instanteous spindle reversal while threading by swich shaft lever attached with carriage.

• Wide variety of optional accessories for higher productivity.

Interchangeability:

All components machined using jigs & fixtures on imported mother machines to close tolerances thus providing easy interchangeability.

Technical Specifications for model : HGN-1, 2, 3, 4, 5, 6

| Capacity | Standard | Optional | ||

| Centre height over flat ways | mm | 235 | 305 | |

| Swing over bed | mm | 455 | 595 | |

| Swing over cross slide | mm | 255 | 395 | |

| Swing in gap | mm | 760 | 900 | |

| Width of gap in front of face plate | mm | 200 | 200 | |

| Bed width | mm | 325 | 325 | |

| Admit Between Centers | Bed Length | |||

| 235/1 | mm | 1035 | 2200 | |

| 235/2 | mm | 1550 | 2700 | |

| 235/3 | mm | 2000 | 3170 | |

| 235/4 | mm | 2500 | 3670 | |

| 235/5 | mm | 3200 | 4380 | |

| 235/6 | mm | 4000 | 5280 | |

| Main Spindle | ||||

| Spindle nose dia./threads | mm/TPI | 74.6x6TPI | ||

| Spindle bore dia. | mm | 52 | ||

| Taper bore in spindle | MT-6 | |||

| Carriage | ||||

| Cross slide travel | mm | 240 | 310 | |

| Compound slide travel | mm | 120 | ||

| Tail Stock | ||||

| Sleeve dia. | mm | 60 | ||

| Taper bore in sleeve | mm | MT-4 | ||

| Sleeve travel | mm | 180 |

| Speeds | |||

| Number / Range | RPM | 8 / 35-1500 | |

| Feeds | |||

| Number | 54 | ||

| Range: | |||

| Longitudinal | mm/rev | 0.017 to 0.998 | |

| Cross | mm/rev | 0.0041 to 0.2410 | |

| Lead Screw | |||

| Diameter/Threads | mm/TPI | 38/4 | |

| Threads | |||

| Range: | |||

| Metric | No./Pitch (mm) | 17/0.5 to 6 | |

| Inch | No./TPI | 54/224 to 4 | |

| Electrical | |||

| Power supply | 440 V, 3 Phase, 50 hz | ||

| Main motor | KW (HP) | 3.7 (5) | |

| Coolant motor | KW (HP) | 0.11 (0.5) | |

| Accuracy | |||

| Geometrical and practical accuracies, Confirm to IS: 1978 (Part l) 1993. |

| Dimension | |||||

| Model | Floor Space occupied (mm) | Approx weight (kg) | Approx size of case (mm) | Volume of case (mt≥) | |

| Nett | Gross | ||||

| 235/1 | 2440 x 1450 | 1575 | 1825 | 2740 x 1105 x 1370 | 4.15 |

| 235/2 | 3010 x 1450 | 1675 | 1975 | 3200 x 1105 x 1370 | 4.84 |

| 235/3 | 3460 x 1450 | 1875 | 2225 | 3700 x 1105 x 1370 | 5.60 |

| 235/4 | 4125 x 1450 | 1975 | 2375 | 4370 x 1105 x 1370 | 6.62 |

| 235/5 | 5000 x 1450 | 2500 | 3500 | 5070 x 1105 x 1370 | 7.68 |

| 235/6 | 5780 x 1450 | 3200 | 4200 | 5800 x 1105 x 1370 | 8.78 |

Standard Accessories

Four position square tool post. Driving plate. Centre adaptor. Dead centers (MT-4-2 Nos) Electric motor, starter. Spindle reversal shaft. Change gear set for metric and inch threads. Thread dial indicator. Tool post spanner Instruction Manual, V-Belt, Norton Gear box.

Optional Accessories

Taper turning attachment (300 length x 250 Dia. max) Coolant pump with tank and electrical fittings. Machine lamp. Long cross slide with rear tool post. three jaw self centering and four jaw independent chucks. Chuck flange. Quick change tool post. 305 mm heigh of centre. Face plate, Steady rest, Follow rest, Rear splash guard.

Note : As improvements are constantly made in our machine, the specification are subject to change without notice and are not binding on us.

10000+ Clients

20000+ Installations

Over 27+ Years of Experience

India's No.1 Machine Tools Distributor

New Delhi:

B-73, Phase-1, Mayapuri Industrial

Area, New Delhi - 110064

+91-11-28117865/67

Gurgaon: