Estd. 1987

Sales: +91-9810112341 | Technical Support: +91-9212268113

Delhi ι Gurgaon

Features

• GRADE – 25 HARDENED AND GROUND BED GUIDEWAYS.

• HARDENED & GROUND ALLOY STEEL GEARS & SPINDLE IN HEAD STOCK

• HARDENED & GROUND TAIL STOCK RAM

• ALL CRITICAL COMPONENTS LIKE SHAFTS, GEARS, PINS, LEAD SCREW ARE MADE OUT OF EN-8/ EN-9 ALLOY STEEL

• ACCURACY CONFORMS TO INDIAN STANDARD No. I.S. : 1878 (PART - l) – 1993.

Salient Features:

• IS.20/25 graded casting

• Rigid and box section type 240 mm wide bed provides maximum torsional stiffness.

• Rigid and accurate, alloy steel hardened and ground main spindle mounted on precision taper roller bearings & ball bearings.

• Forced lubrication in universal feed gear box. Apron with oil bath.

• Thread and feed mechanism interlocked (Only one can be engaged a time).

• Camlock spindle nose (DI-4 type)

• Overload Protection through suitable relays and contractors.

• Switch shaft lever fix at carriage to rev. forward & stopped main spindle.

Built-in Accuracy:

• All major castings are artificially seasoned for retaining built-in accuracy.

• Critical components precision machined on imported mother machines.

• Induction hardened and alloy steel gears of head stock mounted on precision spined shaft and running in oil bath.

• Flame hardened and ground bed for sustained accuracy.

• Alloy steel lead screw threads produced on WMW thread milling machine.

• Each machine is tested to IS-1878 (Part) 1993.

Versatility:

• Built-in gap bed.

• Universal feed gear box for easy selection of wide range of feeds and threads through levers. No change gears required.

• Instantaneous spindle reversal while threading.

• Wide variety of optional accessories for higher productivity.

Interchangeability:

• All components are machined using jigs and fixtures on imported mother machines to close tolerances thus providing easy interchangeability.

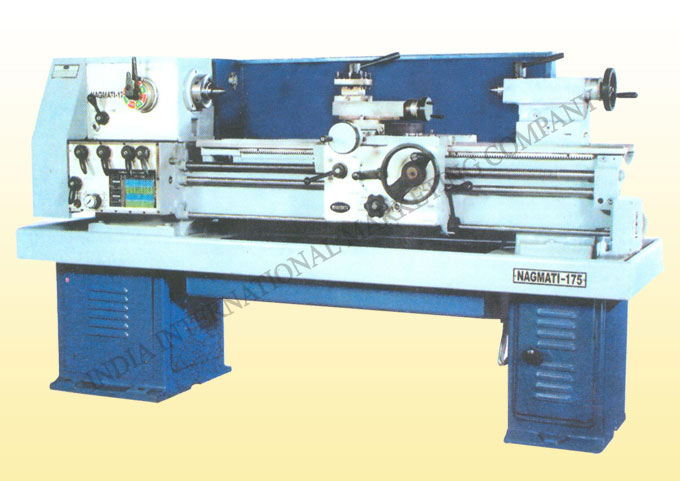

Technical Data

| Centre | Height | 175 mm | |

| Admit between Centre | 650 or 1000 mm | ||

| Swing | Over bed | 350mm | |

| Over cross side | 215 mm | ||

| In gap | 540mm | ||

| Spindle | Bore | 41mm | |

| Nose | Camlock Di-4 (IS 2582 Part 11-1972) |

||

| Morse taper in nose | MT. No.5 | ||

| Morse taper in nose bush | MT. No.3 | ||

| Speed | Number | 8 | |

| Range | 54 to 1200 or 67 to 1500 r.p.m. |

||

| Motor | 1440 r.p.m. 50 cycles. 3 phase AC power 2.25 KW/3 H.P. |

||

| Lead Screw | Diameter | 28 mm | |

| Thread | 6 mm pitch | ||

| Thread | Metric pitches | From 05. mm to 6 mm | |

| British pitches | From 4 to 60 TPI | ||

| Feeds | Longitudinal | From 0.089 mm to 1 .330 mm per rew |

|

| Cross | 0.5 times of longitudinal feeds |

||

| Tailstock | Quill diameter | 50 mm | |

| Quill travel | 140 mm | ||

| Taper | M.T.-3 | ||

| Net weight | 950 kgs. | ||

| Gross weight Shipping | 1150 kgs. | ||

| Dimensions | Length | 2.14 m | |

| Width | 0.95 m | ||

| Height | 1.5m | ||

| Volume | 3.5 cu. m. |

Construction

Head stock8 different speeds possible. The headstock is all geared type, having splash lubrication. It houses the main spindle and the gears (for 8 different speed). The drive is taken from the motor, which is housed inside the left pedestal. And, the speed changeover levers are conveniently placed – to ensure quick setting of the required speed. The headstock is well seasoned and the gears are hardened and ground. what’s more the bed other castings are all made to ISI standards.

Feed gear box

Is provided with a feed gear box for cutting inch and metric series threads. Setting of the correct pitch is quick, and can be done easily by using the changelevers and knob. The gears however, are lubricated by a plunger pump driven by an eccentric pin and a cam. No gear charging is required.

Apron with oil bath

The apron design is of the ‘totally enclosed’ type and comprises an oil bath, in which the gears of the apron run. The half nut lever is interlocked with the feed lever so that only one can be operated when the other is not in use. And, both the sliding and the surfacing feed can be engaged by the friction clutch lever.

Rigid tail stock

It is robust in construction and is fitted on a separate vee guide on the bed; this ensures highly accurate alignment along the entire length of the tailstock. Further, It can be set over on either side, for turning small tapers. And, it is possible to clamp the tailstock casting along the bed by using a single levered cam type clamp.

Standard Accessories

All machines are equipped with motor and complete electricals for 415 volts, 50 cycles, 3 phase supply. Carrier plate, Centre bush, 2 Nos. MT-3 Dead centres, tool post spanner, thread dial indicator, 4- way tool post, camlock operating handle & Instruction manual.

Optional Accessories

Face plate, Steady rest, Follow rest, Coolant pump with thanks and fittings, Taper turning. Attachment, Chuck flanges, 3 Jaws selfcentering chuck, back plate, Rear tool post, machine lamp. Rear splash guard, foot brake, 4 Jaws dog chuck.

Note : As improvement are constantly made in our machine, the specification are subject to change without notice and are not binding on us.

10000+ Clients

20000+ Installations

Over 27+ Years of Experience

India's No.1 Machine Tools Distributor

New Delhi:

B-73, Phase-1, Mayapuri Industrial

Area, New Delhi - 110064

+91-11-28117865/67

Gurgaon: